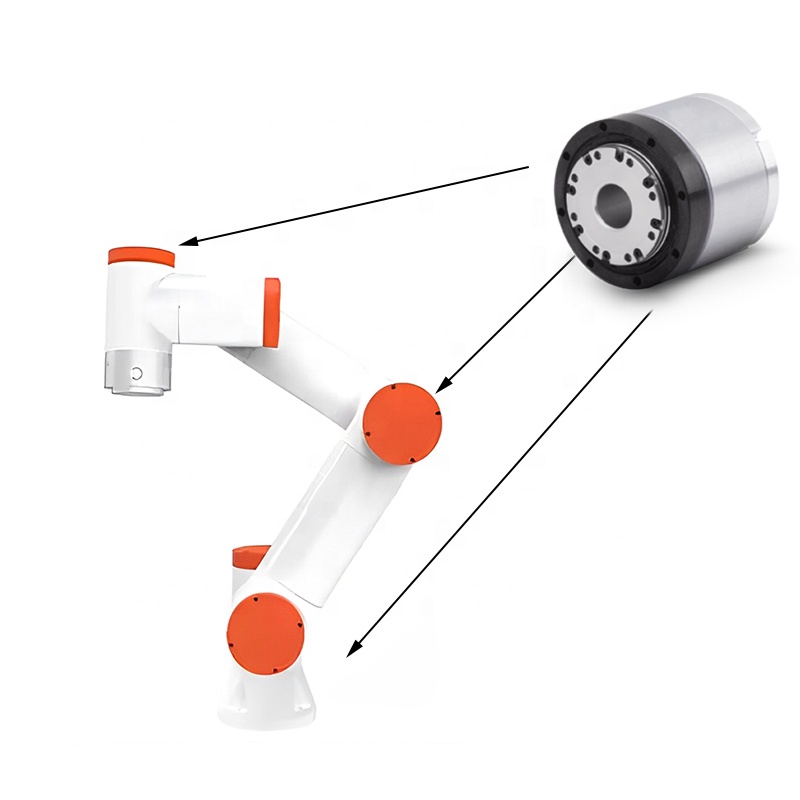

The performance of the joints directly determines the accuracy, speed and flexibility of the robot's movement. Among different types of robots, due to the differences in working environments and task requirements, there are also variations in joint configurations and the key components adopted. Among them, the common shape design mostly adopts a modular approach, integrating the motor, reducer, driver, encoder and other sensors into one unit to form a power output unit.

From the perspective of the composition of the joint components, it is as a whole composed of an absolute encoder at the motor end, a multi-turn absolute encoder at the output end, a frameless torque motor, a harmonic reducer, a brake retainer, a servo driver and a torque sensor.

Among them, the encoder is equivalent to a precise "Angle feedback system" of the machine. It can monitor the position of the robot's joints in real time and feed this information back to the control system.

Take medical robots as an example. Medical robots are mostly used in surgeries inside the human body. Therefore, they have extremely strict requirements for the repeat positioning accuracy of core components, power consumption and heat generation, safety protection, and torque control.

In humanoid robots, encoders can achieve more precise control of joint positions, ensuring that the robots can accurately reach the target positions during operations such as material handling and parts assembly, thereby enhancing production efficiency and product quality. This can be applied in scenarios such as parts assembly on automotive parts production lines.

Compared with other joint modules of the same load capacity on the market, it has the smallest volume. The feature of achieving high torque output in a small size has significant advantages in practical applications. For instance, in the logistics and warehousing scenario, users will select the joints of the smallest modules to drive the robots within a limited environment, meeting the flexible operation requirements in a confined warehouse space. In surgical robots, smaller joint volumes can reduce the spacing between multiple surgical robotic arms, and various surgical instruments can perform surgical operations through smaller wounds. Furthermore, the smaller joint volume also provides the possibility for the external dimensions of humanoid robots to continuously approach the real human body size.

If you need information about our products, please contact us at info@arcsecobot.com

Hangzhou Aike Automation Co., Ltd.

Hangzhou Aike Automation Co., Ltd.